PEA020-800-Y80S 3D Vision Sensor: Real-Time Depth Perception For Industrial Applications

PEA020-800-Y80S is a cutting-edge solution based on active binocular stereo vision technology and RGBD image segmentation, designed for high-precision, high-resolution data capture under various lighting conditions. With millimeter-level depth perception, this system excels in applications such as volume measurement, part counting, dual detection, boundary detection, and position correction. The PEA020-800-Y80S is highly customizable for different scenarios, ensuring accuracy and efficiency in logistics, manufacturing, and automation processes. Key features include real-time 3D scanning, accurate part identification, and error reduction in sorting and transport, boosting operational efficiency and reducing errors.

- Pyroglaux

- China

- Information

PEA020-800-Y80S: High-Precision 3D Measurement and Detection for Enhanced Logistics and Automation

The PEA020-800-Y80S is a state-of-the-art system combining active binocular stereo vision technology and RGBD image segmentation to deliver real-time, high-precision depth perception with millimeter-level accuracy. This innovative solution is designed to address the growing challenges faced by dealers and end customers in industries such as logistics, manufacturing, and automation. With the ability to operate under various lighting conditions, the PEA020-800-Y80S ensures reliable performance and versatility across diverse applications.

Key Features of PEA020-800-Y80S

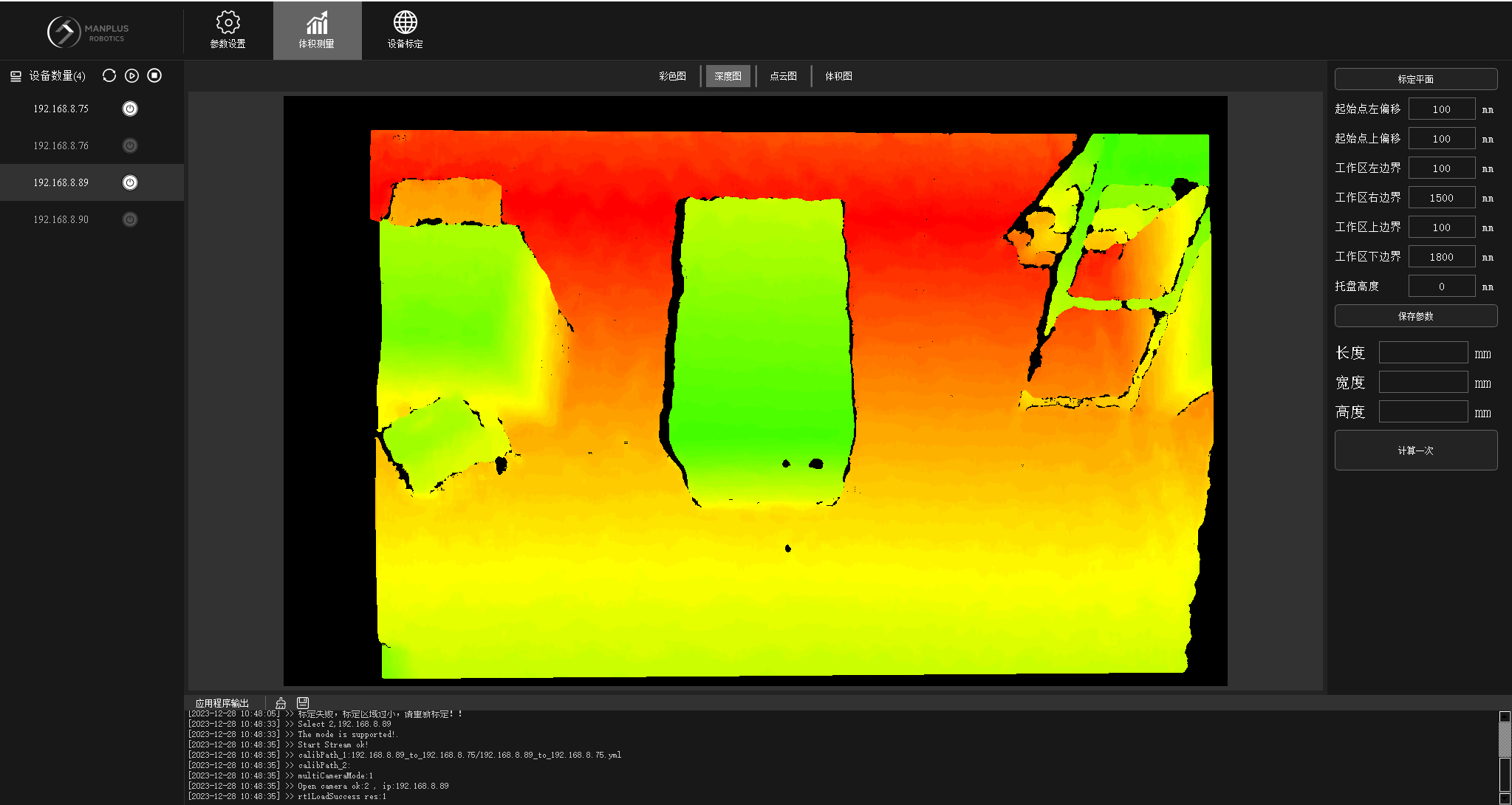

Accurate Volume Measurement

The PEA020-800-Y80S excels in both regular and irregular volume measurements, making it suitable for a wide range of items, from large goods to thin products. This precision helps overcome the limitations of traditional measurement methods, improving efficiency and accuracy in sorting and handling.

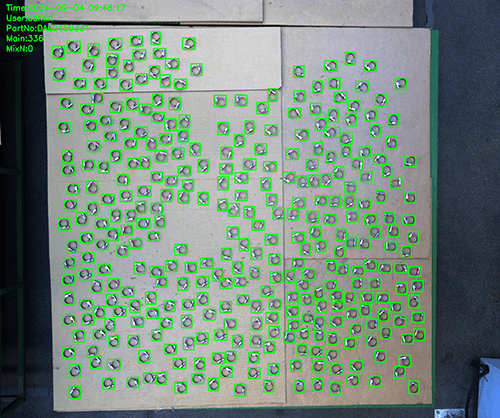

Part Counting and Identification

By scanning the surface of parts and performing 3D reconstruction, the PEA020-800-Y80S can accurately identify, classify, and count individual components. This is essential for industries like manufacturing, where accurate part counting is crucial for inventory management and production processes.

Dual Detection for Error-Free Sorting

One of the standout features of the PEA020-800-Y80S is its ability to perform real-time dual detection. By capturing 3D data, the system effectively reduces errors caused by package stickiness or overlap during sorting, which is a common issue in fast-paced logistics environments. This leads to more efficient sorting and higher throughput.

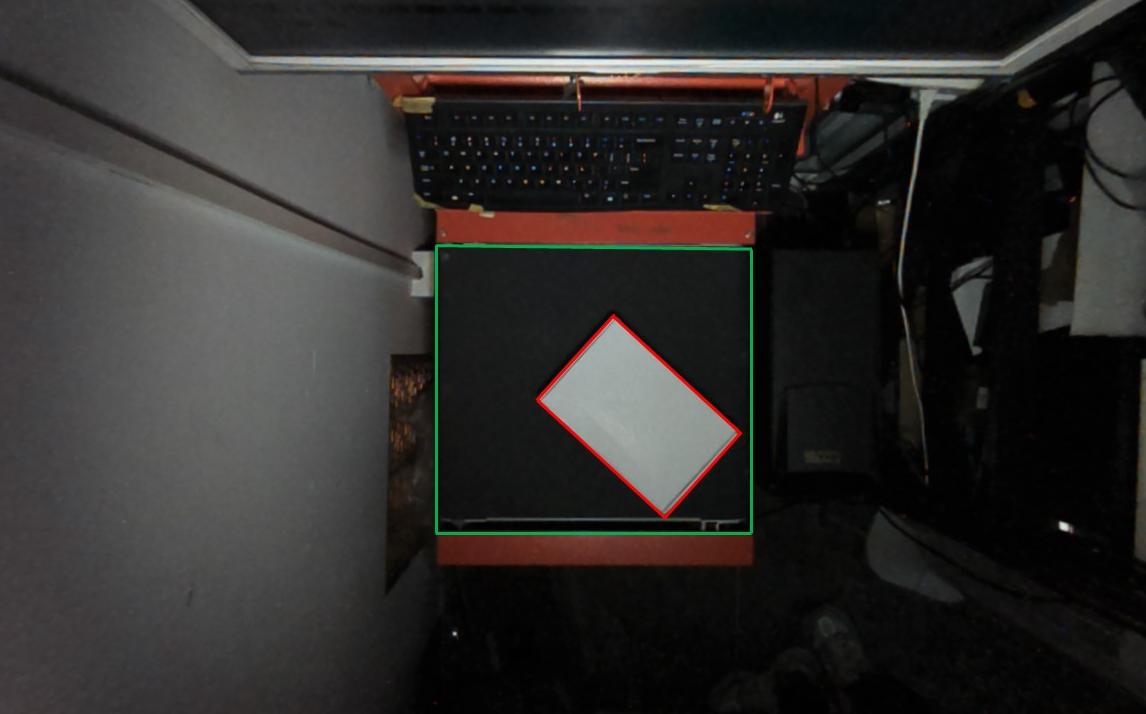

Boundary Detection for Package Size Compliance

The PEA020-800-Y80S also offers boundary detection to identify whether packages exceed preset size limits. This is crucial for preventing system errors such as conveyor jams, sorting mistakes, or safety issues during loading. It ensures that packages remain within the allowed size range during transport, sorting, and handling.

Position Correction for Precise Package Handling

The system's position correction feature allows the PEA020-800-Y80S to automatically adjust the position of packages based on their detected coordinates. This ensures that packages are correctly aligned, reducing the chances of damage, conveyor belt jams, and sorting errors, enhancing operational reliability.

Empty Pallet Detection to Optimize Workflow

The PEA020-800-Y80S also includes an empty pallet detection function, which allows the system to distinguish between loaded and empty pallets. This ensures that only pallets with goods are processed, avoiding unnecessary processing of empty containers and improving resource efficiency in automated systems.

High Customization for Varied Applications

The PEA020-800-Y80S can be tailored to meet specific operational needs. Whether for high-speed part counting or large-scale volume measurements, this flexible solution offers customization options that make it ideal for a wide range of industries, including logistics, manufacturing, and automation.Improved Sorting Efficiency and Reduced Errors

Through advanced RGBD image segmentation and real-time 3D scanning, the PEA020-800-Y80S provides high-accuracy measurements that help improve sorting efficiency. With fewer sorting errors, companies can reduce costs associated with reprocessing, handling, and lost inventory.Enhanced Logistics and Automation Workflow

By integrating PEA020-800-Y80S into logistics and automation systems, businesses can optimize their operations. The system's precision, adaptability to various lighting conditions, and comprehensive detection features help streamline workflows, reduce operational bottlenecks, and enhance overall efficiency.Future-Proof Technology for Evolving Industry Needs

As industries continue to adopt automation technologies, the PEA020-800-Y80S is designed to support future advancements in logistics, manufacturing, and distribution. Its ability to provide accurate, real-time 3D measurements ensures that businesses are equipped to handle evolving industry demands and technological shifts.

Conclusion

The PEA020-800-Y80S is the ideal solution for dealers and end customers seeking to enhance their logistics, manufacturing, and automation processes. With its precision in volume measurement, part counting, dual detection, boundary detection, and position correction, the system addresses key pain points such as sorting errors, package misalignment, and workflow inefficiency. By integrating the PEA020-800-Y80S into their operations, businesses can improve operational efficiency, reduce errors, and optimize resources, positioning themselves for success in an increasingly automated world.